Do more with less effort - what's Field Service Management?

Based on the last incident mLogistics® realises dynamic scheduling and 100% end-to-end service management

Do more with less effort – what's Field Service Management?

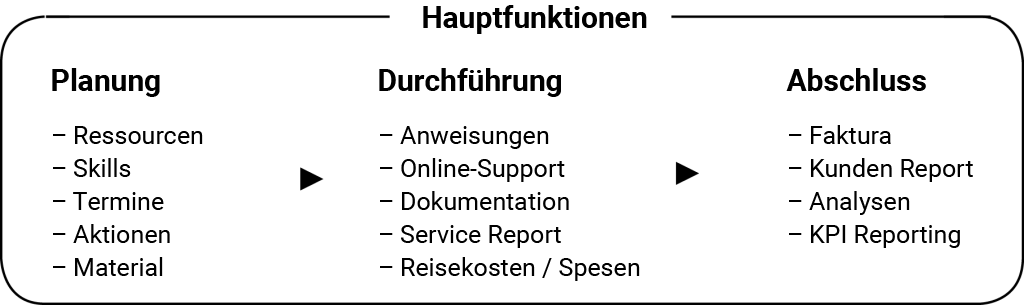

Field Service Management is the control of the Mobile workforce at a Customer site to maintain equipment and resolve service requests or problems.

By optimising the scheduling of resources and timely material supply, there are potentially enormous cost savings and revenue enhancement opportunities. The right technician with the right material and with direct support from their office enables problems to be solved instantly on the first visit. This saves costs and increases Customer satisfaction.